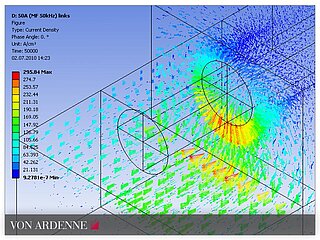

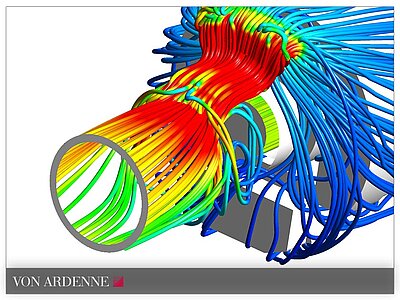

Elektromagnetische Simulationen

Was?

Modellierung von

- Elektrische Spulen

- Dauermagneten

- Ferromagnetische Materialien mit nichtlinearen B-H-Kurven und Hysteresen

- DC- und AC-Prozesse

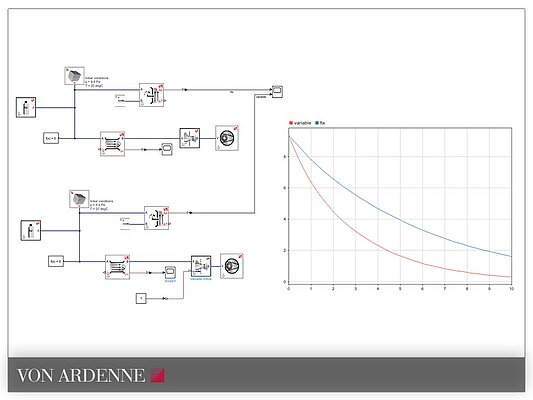

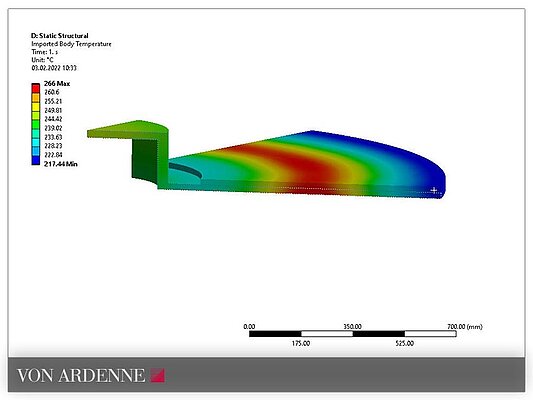

- Elektrothermische Kopplung

- Elektromagnetische Kopplung

Womit?

- Ansys

- Comsol

- CST/Opera

Wofür?

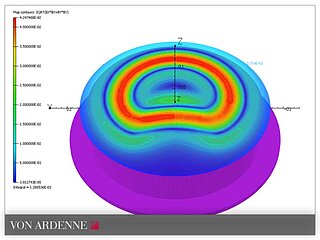

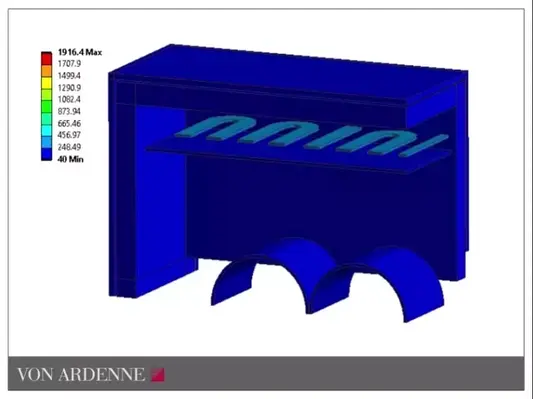

- Elektrische und magnetische Felder

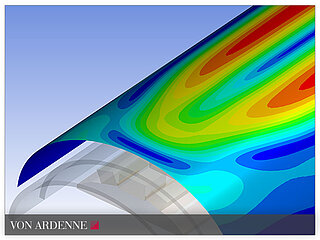

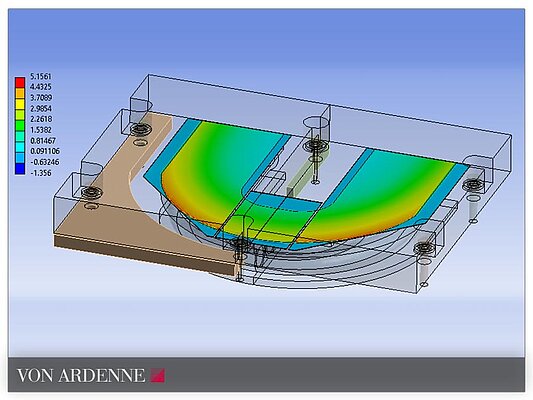

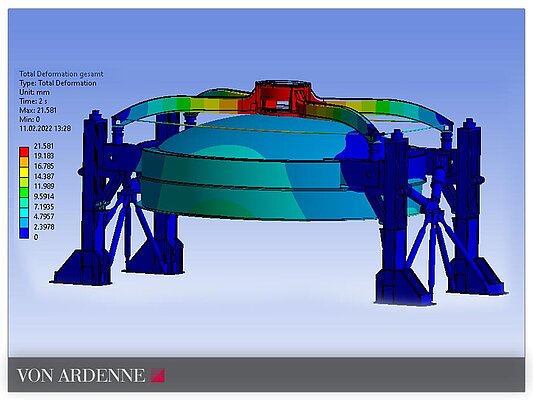

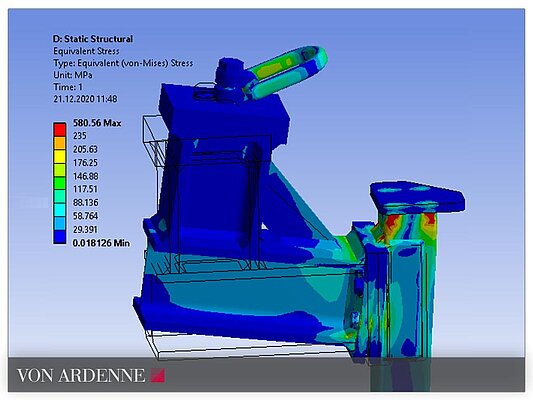

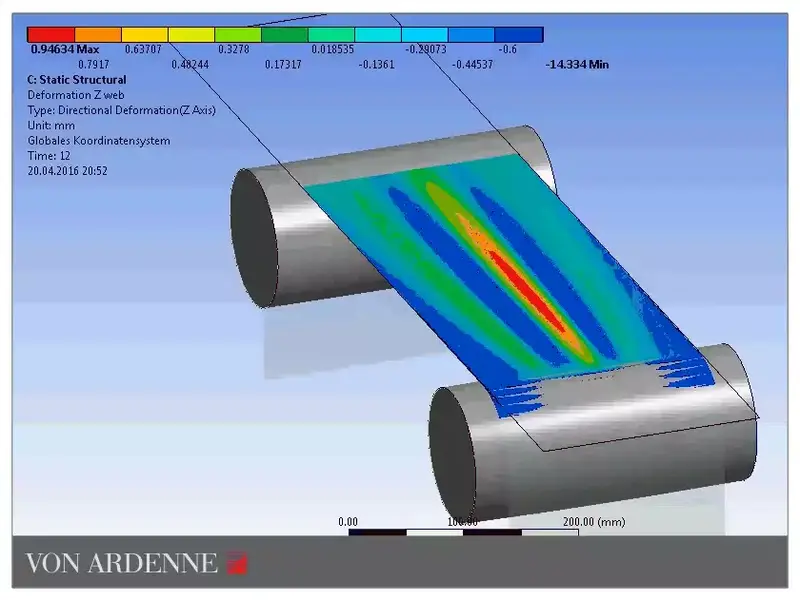

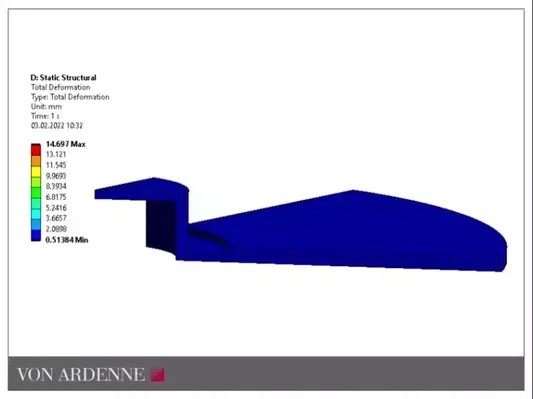

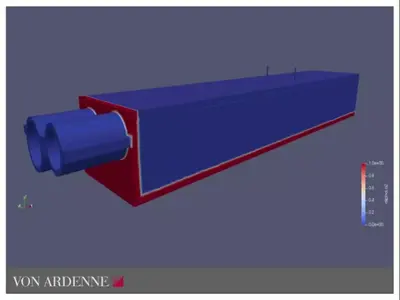

- Thermisch induzierte Verformung und Spannung

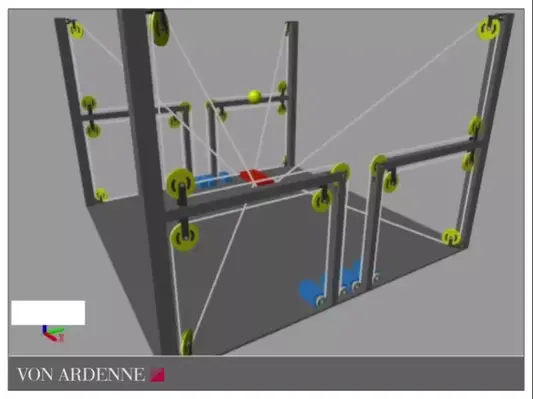

- Kräfte und Momente aus elektromagnetischen Feldern

- Skin-Effekte und bewegungsinduzierte Wirbelströme

- Magnetisierung von Werkstoffen

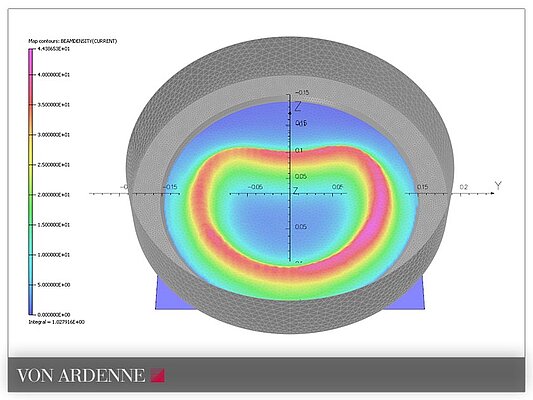

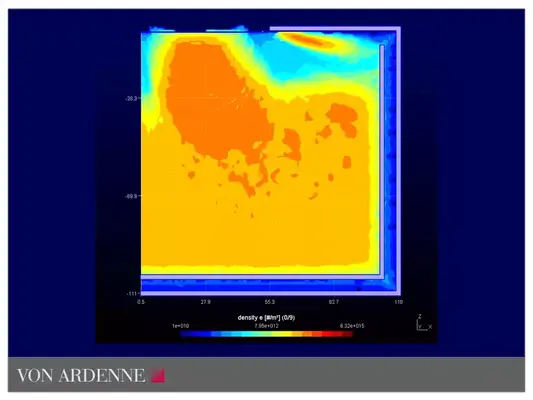

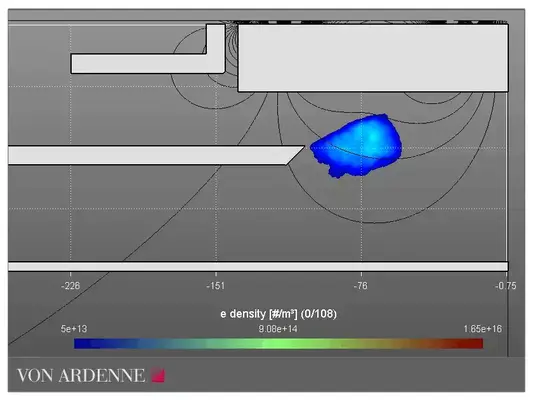

PLASMA-SIMULATION

Was?

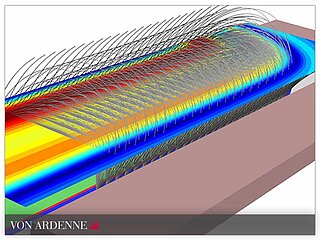

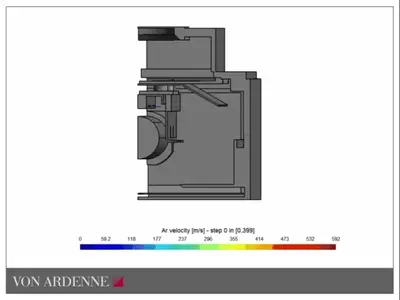

- Simulation von Ladungsträgern (Ionen und Elektronen) unter dem Einfluss von elektrischen und magnetischen Feldern

- Entwicklung von Niederdruckplasmen im Raum

Womit?

- PICMC

- Opera

Wofür?

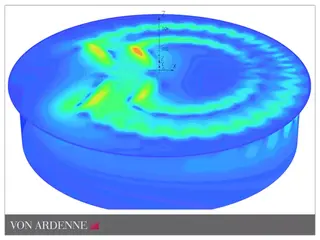

- Einfluss der Kammergeometrie und der Öffnungen sowie der Wirbelströme auf die Plasmabildung

- Verlauf eines Elektronenstrahls unter dem Einfluss des Magnetfelds

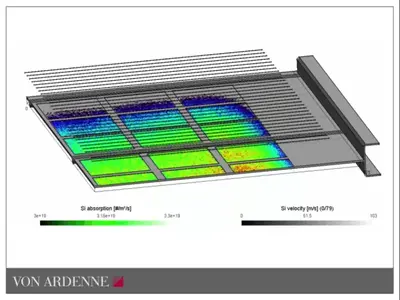

- Intensität und Verteilung der rückgestreuten Elektronen des Elektronenstrahls

- Optimierung von Sputter- und Ätzprozessen